Atmospheric Plasma Spray (APS) Systems are the most versatile a flexible thermal spray process due to its ability to spray a wide range of materials such as most metals, ceramics and alloys onto many different substrate materials such as plastics, glass, metals, ceramics and composite materials. Also, a broad range of powder particle sizes can be used. Benefits of APS include resistance against heat, oxidation and wear, corrosion protection, clearance control for abrasives and abradables, temperature management as well as electrical resistivity and conductivity. Thus APS can be used for a wide range of applications across industries

Typical coatings

Ceramics

Carbides & Cermets

Iron, Nickel & Cobalt based alloys

Main applications

Wear resistance, Sliding, Abrasive, Erosion, etc

Corrosion resistance

Thermal Barrier Coatings (TBC) on turbine components of any size

Hard-facing coatings for better fretting resistance on combustion parts

WC coated

WC coated

YSZ coated

YSZ coated

YSZ coated

Inner Case

Inner Case

Inner Case

Inner Case

Inner Case

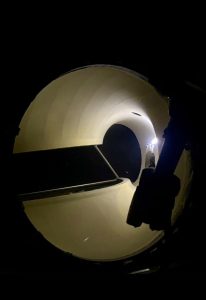

Combustion Chamber